Dealing with error messages after upgrading to LED bulbs? Canbus resistors are key for a seamless transition. This guide cuts through the complexity and gets straight to how a Canbus resistor makes your vehicle’s Canbus system LED-ready. We’ll explain their function and show you the correct way to install them for a smooth, error-free experience.

Key Takeaways

- Canbus systems meticulously prioritize signals for vehicle ECUs, and proper resistor installation is crucial to maintain the network’s performance when making LED upgrades.

- LED bulbs are energy-efficient, long-lasting, and environmentally friendly, but they can cause complications with Canbus systems, such as hyper flashing and error messages, which are solved by using the right Canbus resistors.

- Installing a Canbus resistor involves connecting it to the vehicle’s wiring system to simulate the load of halogen bulbs, preventing error messages, with tools and detailed instructions available in kits like the SYLVANIA load resistor kit.

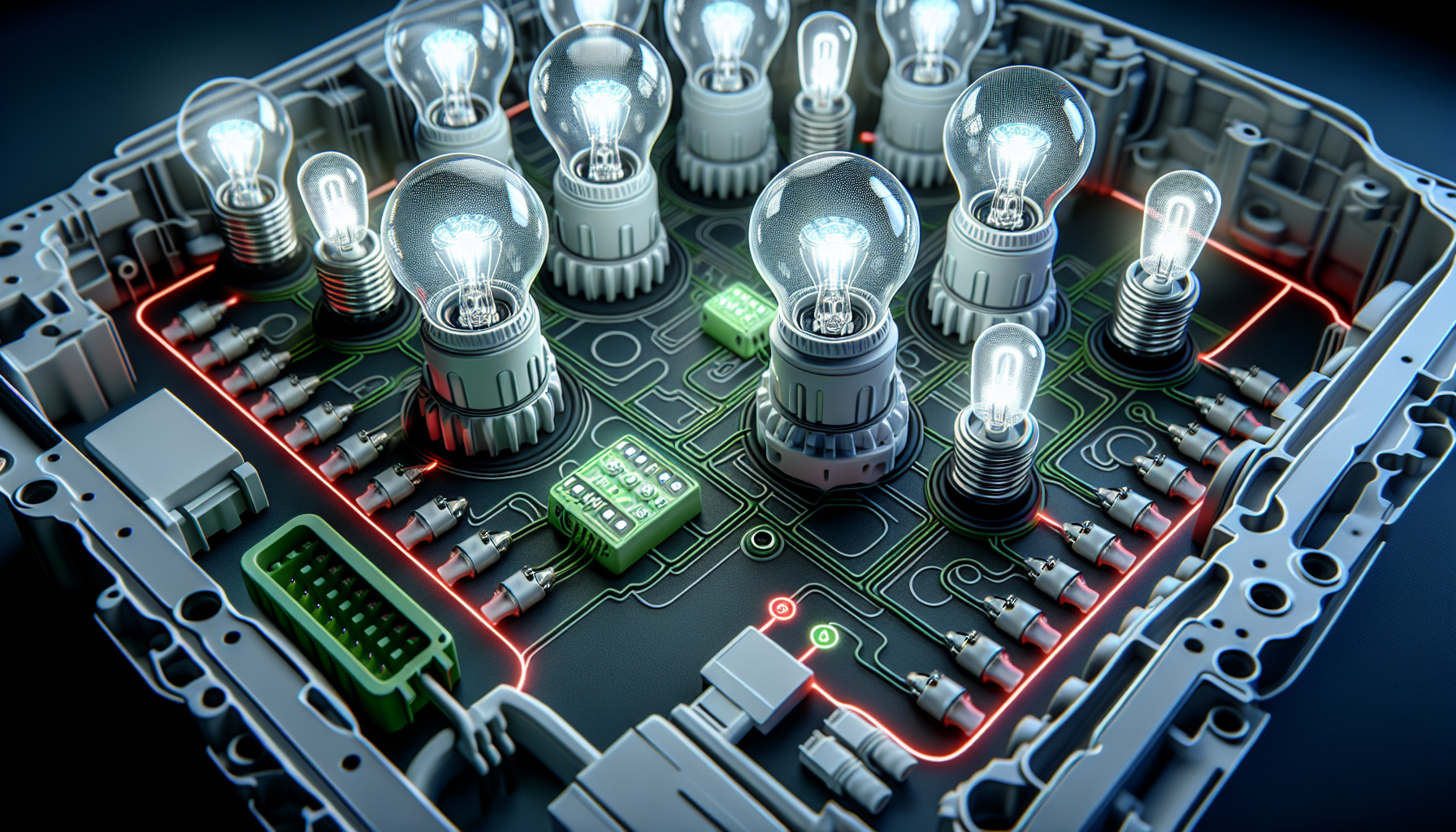

Understanding Canbus Systems

At the core of most modern vehicles lies the Canbus system, a complex network that seamlessly communicates with numerous electronic control units (ECUs). This intricate system is designed to:

- Weather the storm of electric disturbances

- Handle the cacophony of electromagnetic interference

- Ensure that critical messages are always prioritized and delivered without the need for a central computing overseer.

The reliability of this network is not by chance but by design. The Canbus system is meticulous about message priority, assigning urgency through identifiers where lower values signal greater importance. This attention to detail extends to the physical realm, where the system’s performance hinges on the proper installation of resistors and precise cable lengths tailored to specific data rates, ensuring that components are connected directly.

LED Upgrades and Canbus Compatibility

In the field of lighting, LED technology has taken the spotlight, revolutionizing vehicle headlights and other illumination needs. The synergy between LED bulbs and the Canbus system is not just about achieving a modern look; it’s an exercise in enhancing energy efficiency and extending the lifespan of the lighting components. However, this interplay is not without its challenges, as the Canbus system was not originally designed with the low power draw of LEDs in mind.

Advantages of LED Bulbs

The allure of LED bulbs lies in their remarkable energy efficiency, consuming up to a staggering 90% less power than their incandescent predecessors. This frugality in power usage not only translates to cost savings but also lessens the strain on your vehicle’s power source, a nod to both your wallet and the environment. What’s more, the longevity of LEDs is not characterized by a sudden snuffing out but rather a gradual dimming, ensuring they shine reliably for many years.

These bulbs, also known as led headlight bulbs, are stewards of the environment, free from the burden of mercury, and devoid of complex disposal rituals required for hazardous materials. Their small stature belies their versatility, paving the way for innovative lighting designs and applications that can mold to the contours of futuristic vehicle aesthetics. Brightness, too, is a forte of LED headlights, cutting through darkness and inclement weather to offer superior visibility and an added layer of safety on the road. With a led headlight, drivers can experience a significant improvement in their nighttime driving experience, making stock lamps a thing of the past.

Common Canbus Issues with LED Upgrades

The transition to LED lighting, including daytime running lights, can be met with a few electronic hiccups within the Canbus system. One such quirk is hyper flashing, a rapid turn signal blink rate that occurs when the system’s relay does not detect the expected electrical load from the LED turn signals. This, alongside flickering headlights, can be the bane of an otherwise straightforward upgrade, but fret not, for these issues can be remedied with the installation of a load resistor that adjusts the electrical load to a level the relay recognizes.

The intelligence of the Canbus system can sometimes be its Achilles’ heel, as it may misinterpret the efficient current draw of LEDs as a bulb failure, leading to false error messages. To prevent this, selecting the appropriate Canbus resistors is paramount, ensuring they complement both the vehicle’s system and the power requirements of the LED bulbs. Indeed, Canbus compatible LED bulbs come with built-in resistors that mimic the characteristics of filament bulbs to appease the system’s vigilance.

The Role of Canbus Resistors

While exploring the complexities of Canbus systems and LED upgrades, we discover the critical role of Canbus resistors. These components are the peacekeepers in the LED-Canbus relationship, ensuring that the system recognizes the upgraded bulbs as fully operational.

By emulating the load of traditional halogen bulbs, these resistors cleverly avert common errors like ‘bulb-out’ warnings and keep the electrical ecosystem in equilibrium.

How Canbus Resistors Work

Canbus resistors are the alchemists of the automotive world, transforming the lower current draw of LED bulbs into a semblance of the halogen power draw. This act of electrical mimicry reassures the Canbus system that all lights are glowing as intended, without any anomalies to report. Like a skilled impersonator, the resistors create just enough resistance to simulate the energy consumption of halogen lights, further convincing the system of the LEDs’ legitimacy.

These resistors, at times referred to as Canbus decoders or load resistors, offer the precise resistance needed for the Canbus system to confirm the proper functioning of an LED bulb. Should error messages persist post-installation, it may hint at a resistance level mismatch, where the resistor is not compensating adequately for the LED bulb’s low power draw.

Choosing the Right Canbus Resistor

The quest for the right Canbus resistor is akin to finding the perfect key for a lock. The resistor’s value, often ranging between 100 to 130 ohms, must be meticulously chosen to prevent electrical reflections and ensure network harmony. For those who favor ease over enigma, plug-and-play Canbus decoders offer a no-fuss installation, bridging the gap between the vehicle’s wiring system and the new LED bulbs seamlessly.

In the pursuit of reliability, turning to established manufacturers with a track record of positive feedback is wise. Their resistors undergo compatibility testing for specific vehicle models, ensuring a smooth transition to LED lighting. For vehicles that turn their noses up at standard Canbus compatible LED bulbs, resistor kits come to the rescue, tweaking the circuit resistance to quell any error messages that may arise.

Step-by-Step Guide to Installing a Canbus Resistor

Equipped with the knowledge of Canbus systems and the role of resistors, one might wonder how to embark on the installation journey. The process is straightforward, but attention to detail is key. A successful installation not only restores proper function to your LED lights but also extends the life of your investment.

Let’s illuminate the path to installing a Canbus resistor.

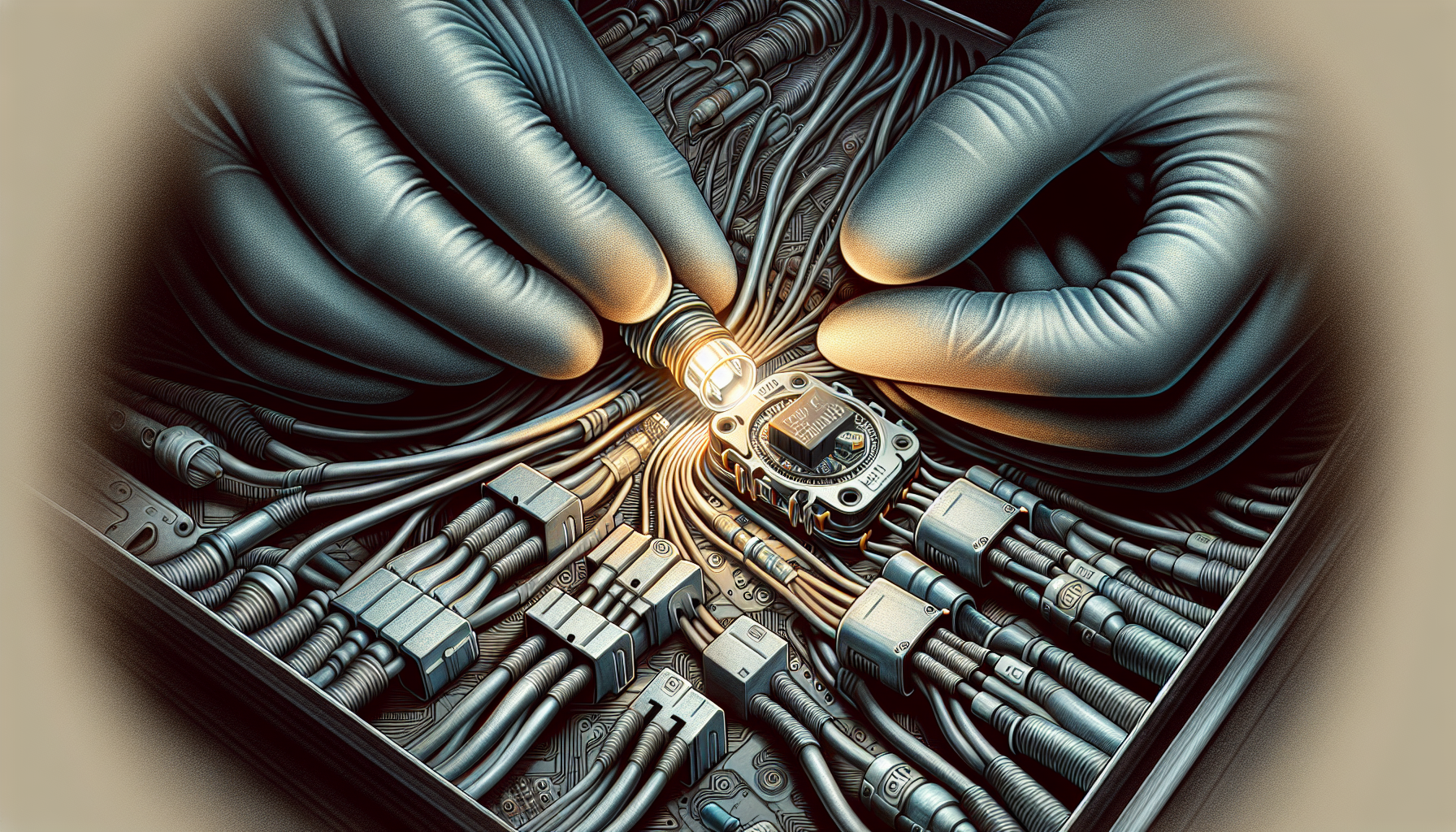

Tools and Materials Needed

Before starting, it’s necessary to assemble the tools and materials required. At the core of our toolkit are the 50W 6 OHM load resistors, the stalwarts that will ensure our LEDs and Canbus system see eye to eye. Alongside these, we’ll need wire splicing tools—wire strippers or a trusty knife—to connect our resistors to the vehicle’s harness.

A complete kit like the SYLVANIA load resistor kit, which also functions as a load equalizer, comes with all the essentials: two load resistors, wire connectors, and ties to keep everything tidy and secure. With these components at the ready, we’re poised to tackle the installation with confidence.

Installation Process

Now, let’s proceed with the installation process. For single filament applications, we’ll connect the load resistor wires between the positive and negative wires. In the case of double filament bulbs, finding the brightest mode wire and its ground counterpart is the goal. Merging the load resistor wires directly with the vehicle’s harness is preferred for a robust connection, sidestepping the pitfalls of less reliable methods like T-taps.

After all wires are securely connected, it’s essential to cover any exposed wiring with electrical tape for protection. The load resistor itself will be zip-tied to the vehicle’s metal body, an essential step for managing the heat it will generate.

Performing a final test of the led turn signal lights will validate the installation, confirming the resolution of the hyper flash issue and the proper functioning of the turn signal lamps, as well as ensuring the overall performance of the turn signal lights.

Troubleshooting Common Canbus Resistor Issues

With the Canbus resistor now installed, we anticipate a smooth journey ahead. However, sometimes the unexpected occurs, and we find ourselves troubleshooting issues that could arise. Addressing these effectively can make the difference between a flickering frustration and a triumphant, error-free upgrade.

Overheating Issues

Overheating is a potential concern with Canbus resistors, as they are designed to dissipate power in the form of heat. Ensuring that the resistor has ample clearance from other components is critical to prevent the heat from causing any damage, such as melting nearby interior parts. Additionally, incorporating heat sinks or securing proper ventilation can further mitigate overheating problems, maintaining the resistor’s longevity and performance.

If overheating persists, a review of the resistor’s installation and positioning may be in order. Sometimes, a simple adjustment in placement or improving airflow can be enough to keep temperatures within safe limits, ensuring the resistor serves its purpose without causing power issues.

Persistent Error Messages

Despite our best efforts, sometimes error messages continue to plague the Canbus system. Persistent warning signals after installation could indicate that the system is not fully convinced of the LED bulb’s compatibility or that there may be underlying electrical issues. A common indicator of a problem is if the CAN device consistently receives exactly 2.50 VDC, suggesting that the device is on but not transmitting data—a scenario that warrants further inspection.

In such cases, a thorough check of the vehicle’s electrical system is advisable, looking for loose connections or signs of wear. If the issues persist, seeking the expertise of a professional for in-depth diagnostics may be the next step. They can provide a specialized approach to resolving the error messages and restoring the system’s confidence in the LED installation.

Customer Reviews and Experiences

We can gain insights from the experiences of customers who have previously installed Canbus resistors. Many report an easy installation process, a testament to the thoughtful design of the resistor kits and the clarity of the instructions provided. The satisfaction of seeing their turn signals flashing at a normal speed again, without any hyper flash or flickering issues, is a common thread among positive reviews.

The SYLVANIA LED Load Resistor, in particular, has garnered praise for its functionality and reliability. Customers often describe it as a great product, highlighting the ease with which their car headlights began to work perfectly post-installation. Moreover, the peace of mind that comes with a warranty is invaluable, ensuring support and resolution should any product issues arise.

Summary

In the electrified odyssey of upgrading vehicle lighting, the Canbus system and Canbus resistors emerge as pivotal players. From understanding the intricate communications within a vehicle to embracing the bright promise of LED technology, we’ve navigated through the installation and troubleshooting of Canbus resistors. This journey illuminates not only our headlights but also the path to a more efficient and safe driving experience. May the insights gleaned here inspire you to illuminate your own way forward.

Frequently Asked Questions

Do LEDs need a CANbus?

Yes, if you have installed LED headlights in your car and experience flickering, headlight errors, or bulbs staying illuminated after being turned off, you might need a CANbus.

What does a CANbus unit do?

A CANbus unit facilitates communication between Electronic Control Units (ECUs) in vehicles and other devices, using a reliable, priority-driven protocol.

What does CANbus mean for LED lights?

CANbus stands for Controller Area Network Bus and it allows LED lights to work with a vehicle’s advanced computer system, ensuring compatibility.

How do I choose the right Canbus resistor for my vehicle?

Choose a Canbus resistor with a value between 100 to 130 ohms, and opt for established manufacturers with positive customer feedback and compatibility testing for your vehicle model. Additionally, consider plug-and-play decoders for a straightforward installation.

What should I do if my LED lights start overheating after installing a Canbus resistor?

Ensure the Canbus resistor has enough clearance and ventilation to manage heat, and consider consulting a professional if the issue persists.